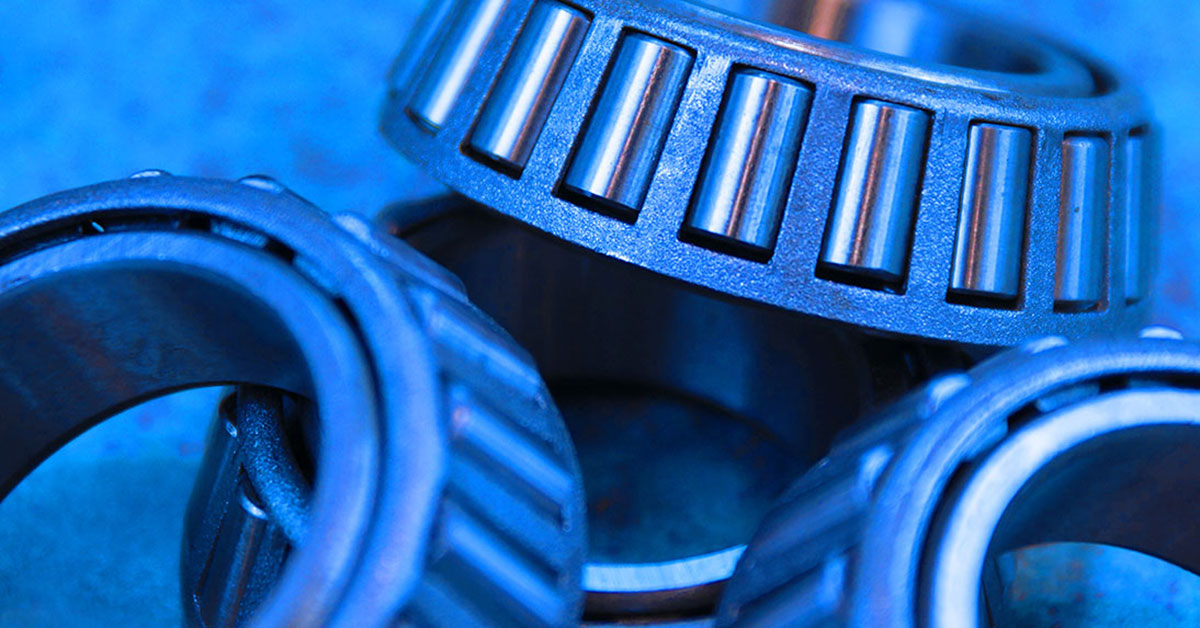

The tapered roller bearing and its applications

By , vendredi le 24 mai 2019, 08:17

The tapered roller bearing is particularly used in automotive applications and heavy machinery. Here are some illustrations of this type of bearing.

Features of tapered roller bearing

The tapered roller bearing consists of an inner ring, an outer ring, tapered rollers and a window cage which serves to hold the rollers in place. Generally, the inner ring, the tapered rollers and the cage that form the cone are all in one piece that can be mounted separately from the outer ring.

The tapered angle allows the tapered roller bearing to support large axial and radial loads in one direction. It is generally necessary to provide axial guidance in the other direction by opposing a second bearing. It is also the angle and the axis of the bearing which determine the ratio between the axial capacity and the radial capacity.

The tapered roller bearing must be serviced. It must therefore be regularly lubricated with grease or oil. It can be used in a variety of environments with temperatures ranging from -30 ° C to +120 ° C. Breakage may occur if the tapered roller bearing moves in extreme temperatures.

Its main applications

The tapered roller bearing is used in many industrial applications. It is ideal for guides that have to undergo extreme loads. It is also found in applications where radial loads are important and rotational speeds are high.

Tapered roller bearings are essential in sectors such as agriculture, construction, mining, engines and propellers. At the industrial level, paper mills, cement plants and oil companies are some examples of environments where tapered roller bearings are found.

Types of tapered roller bearing

Although they are very similar, there are several models of tapered roller bearing, each with certain features. The single row tapered roller bearing is the simplest and most frequently used model. Generally mounted in pairs, it consists of a cone and a cup. There is a variant of this model where the cup is provided with a collar to facilitate axial positioning.

The two-row tapered roller bearing consists of a double cone and two cups. The configuration of this type of bearing ensures a significant effective separation.